Researcher Database

| TANAKA Tatsuya |  |

| Faculty of Science and Engineering Department of Mechanical Engineering and Science | |

| Professor |

Last Updated :2025/07/12

Researcher Profile and Settings

researchmap

Research Areas

- Manufacturing technology (mechanical, electrical/electronic, chemical engineering) / Manufacturing and production engineering

Education

- Doshisha University, 工学研究科, 機械工学専攻, - 1985

- Doshisha University, Graduate School, Division of Engineering, - 1985

- Doshisha University, 工学部, 機械工学第2学科, - 1983

- Doshisha University, Faculty of Engineering, - 1983

Committee Memberships

- 商議員, - Today, 日本機械学会 関西支部

- 代議員, - Today, 自動車技術会

- 理事, - Today, 自動車技術会 関西支部

- 代議員, - Today, 日本塑性加工学会

- 商議員, - Today, 日本塑性加工学会 関西支部

- 理事, - Today, プラスチック成形加工学会

- 2022年度 産業・化学機械と安全部門 代議員, - , 日本機械学会

Published Papers

- Cellulose nanofiber-introduced continuous-ramie yarn-reinforced polylactic acid filament for 3D printing: Novel fabrication process and mechanical properties

Koki Matsumoto; Kenichi Takemura; Ryuta Kitamura; Hideaki Katogi; Tatsuya Tanaka; Hitoshi Takagi

Composites Part A: Applied Science and Manufacturing, Elsevier BV, 176 107836 - 107836, Jan. 2024, Scientific journal - Study on processing conditions for semi-solid forging of magnesium alloys

S.Furuta; H.Nakagawa; T.Tanaka; M.Sasada; S.Nishida; S.Yasuhara; H.Ueno

Solid State Phenomena, 348 21 - 26, Aug. 2023 - 射出成形における可塑化プロセスが樹脂溶融状態へ与える影響

下楠薗壮; 井上玲; 田中達也; 笹田昌弘; 山本良平

成形加工, 35(4) 135 - 140, 2023 - An influence of nanofiller size on the joining strength of injection overmolded component by insert of nanofiller-filled thermoplastics films at interface

Birei Tanaka; Ayaka Hasegawa; Tatsuya Tanaka; Masahiro Sasada; Koki Matsumoto

AIP Conference Proceedings, AIP Publishing, 2023, International conference proceedings - SELECTIVE REINFORCEMENT OF JOINING INTERFACE USING NANOFIBERS IN SINGLE-LAP JOINTS OF THERMOPLASTIC COMPOSITES FABRICATED BY THE INJECTION OVERMOLDING PROCESS: CREEP DEFORMATION BEHAVIOUR

KOKI MATSUMOTO; MASAYA ITABASHI; AKIRA KAWASUMI; KENICHI TAKEMURA; TATSUYA TANAKA

WIT Transactions on The Built Environment, WIT Press, 209 3 - 14, 19 Sep. 2022, Scientific journal - A modified blister mixing element for generating extensional flow in a twin-screw extruder: Process characterization and dispersion state of carbon nanotubes in cyclo-olefin polymer

Koki Matsumoto; Tatsuya Tanaka

Polymer Engineering and Science, Wiley, 62(4) 1223 - 1238, Feb. 2022, Scientific journal - Creep properties of biofiller- and fire retardant-filled polypropylene composites

Koki Matsumoto; Kenichi Takemura; Hitoshi Takagi; Tatsuya Tanaka; Masahiro Sasada

International Journal of Computational Methods and Experimental Measurements, WITPRESS LTD., 9(4) 339 - 351, 16 Nov. 2021, Scientific journal - A mechanism for fire retardancy realized by a combination of biofillers and ammonium polyphosphate in various polymer systems

Koki Matsumoto; Tatsuya Tanaka; Masahiro Sasada; Noriyuki Sano; Kenta Masuyama

Cellulose, Springer Science and Business Media LLC, 28(6) 3833 - 3846, 22 Feb. 2021, Scientific journal - INFLUENCE OF NANOFIBER LOADING AND MOULDING CONDITIONS ON THE JOINING STRENGTH OF THERMOPLASTIC COMPOSITES FABRICATED BY INJECTION OVER-MOULDING PROCESS

KOKI MATSUMOTO; TUKASA NAGASAKA; KENICHI TAKEMURA; TATSUYA TANAKA

WIT Transactions on The Built Environment, WIT Press, 196 113 - 124, 11 Nov. 2020, Scientific journal - Effect of amount of grafted CNT on carbon fiber on interfacial shear strength between carbon fiber and polyamide resin by microdroplet test

K.Tanaka; T.Tanaka; T.Katayama; Y.Morita; K.Watanabe; M.Kawaguchi

WIT Transactions on The Built Environment, 196 51 - 60, 2020, Scientific journal - Experimental investigation of the mechanical, rheological and thermal properties of graphene filled Polypropylene composites produced in a twin-screw extruder.

Maximilian Adamy; Koki Matsumoto; Cristian Hopmann; Tatsuya Tanaka

Zeitschrift Kunststofftechnik, Carl Hanser Verlag, 15(2) 120 - 146, Mar. 2019, Scientific journal - MOLTEM STATE OF THERMOPLASTIC RESIN IN AN INJECTION MOULDING BARREL

So.Shimokusuzono; T.Tanaka; M.Sasada; Y.Hirao; K.Hanafusa; A.Inoue

WIT Transactions on Engineering Sciences, 125 49 - 59, 2019, Scientific journal - Comparison of strength of 3D printing objects using short fiber and continuous long fiber

T.Isobe; T.Tanaka; T.Nomura; R.Yuasa

IOP Conference Series: Materials Science and Engineering, 406 12042 , 2018, Scientific journal - Influence of contents rate and dispersion of carbon nanotubes on interfacial adhesion between continuous fiber reinforced thermoplastics and injection resin

K.Matsumoto; J.Shiode; H.Nishino; T.Tanaka

IOP Conference Series: Materials Science and Engineering, IOP Publishing, 406 12034 - 012034, 2018, Scientific journal - ナノ繊維・粒子を分散制御した熱可塑性複合材料混錬技術<第1報>

松本紘宜; 田中達也

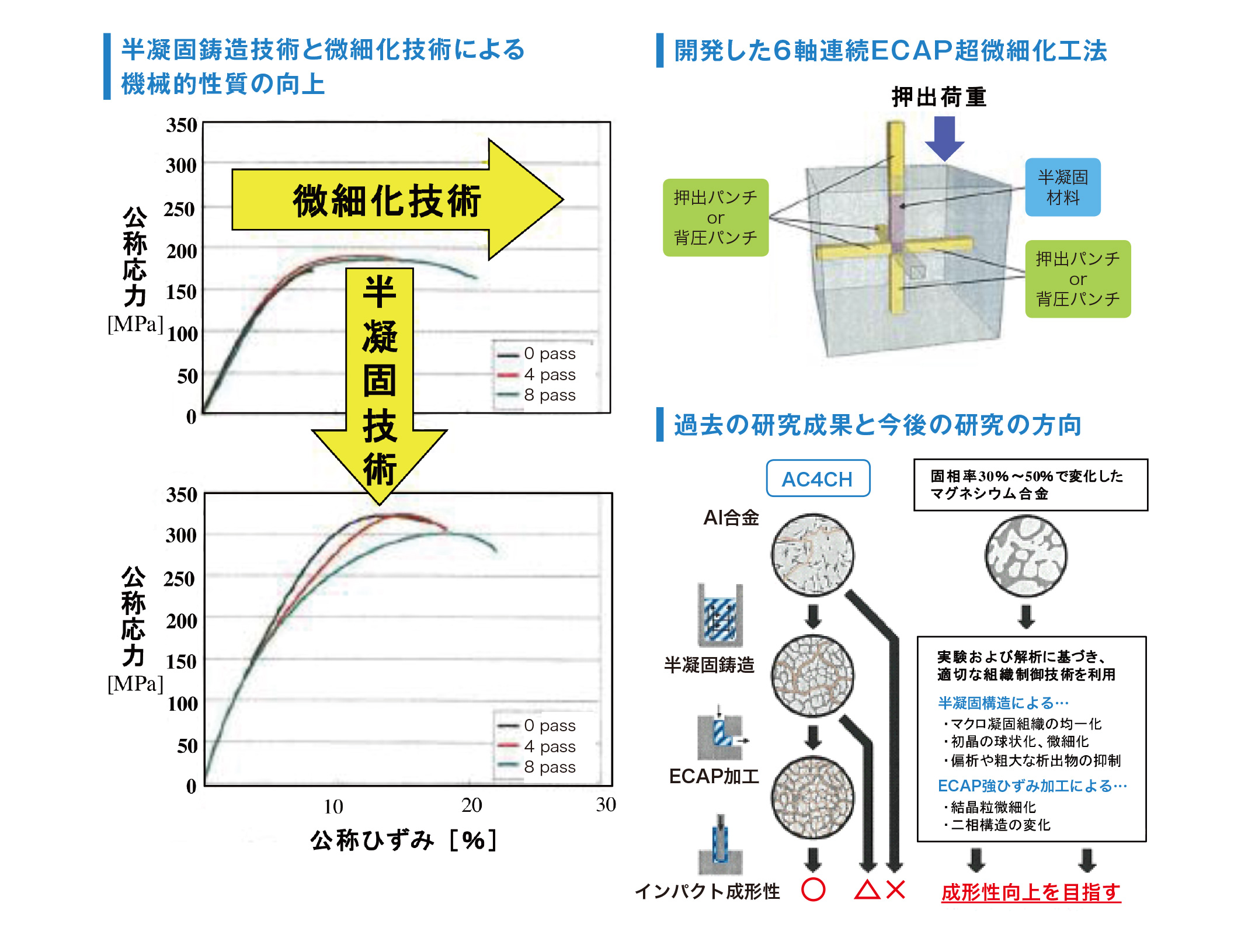

プラスチックス, (8) 101 - 106, 2017, Scientific journal - Improvement in mechanical properties of semi-solid AA 7075 aluminum alloys by Equal-Channel Angular Pressing

G.Horikiri; T.Kitazumi; K.Natori; T.Tanaka

Procedia Engineering, 207 1451 - 1456, 2017, Scientific journal - Influence of Agitation Equipment on Reinforcing Effect and Dispersion State of Cellulose Nano-Fibers in Natural Rubber

S.Omori; T.Morita; K.Matsumoto; A.Nagatani; T.Tanaka

Key Engineering Materials 754 KEM, 137 23 - 26, 2017, Scientific journal - Study of friction and abrasion properties of wood plastic composites

K.Araki; G.Hamabe; Y.Sano; T.Kume; T.Tanaka

WIT Transactions on The Built Environment, 166 403 - 414, 2016, Scientific journal - Improvement in toughness of semi-solid light metal by ECAP process

T.Kitazumi; K.Natori; T.Tanaka

The 2016 International Conference on High Performance and Optimum Design of Structures and Materials, 166 153 - 162, 2016, Scientific journal - The Improvement in Functional Characteristics of Eco-friendly Composites Made of Natural Rubber and Cellulose

Kunihiro Araki; Shonosuke Kaneko; Koki Matsumoto; Asahiro Nagatani; Tatsuya Tanaka; Yoshihiko Arao

PROCEEDINGS OF PPS-30: THE 30TH INTERNATIONAL CONFERENCE OF THE POLYMER PROCESSING SOCIETY, 1664, 2015, International conference proceedings - Comparison of Cellulose, Talc, and Mica as Filler in Natural Rubber Composites on vibration-damping and gas barrier properties

Kunihiro Araki; Shonosuke Kaneko; Koki Matsumoto; Asahiro Nagatani; Tatsuya Tanaka; Yoshihiko Arao

ADVANCES IN RUBBER, 844 318 - 321, 2014, International conference proceedings - Residual Fiber Length and Dispersion of the Thermoplastic Resin Composite Material of Fiber Dispersion Type

TANAKA Tatsuya

The Pigments,Paints and Printing Inks, Japan Society of Colour Material, 86(6) 231 - 236, 20 Jun. 2013 - Study on Failure of Casing : Relationship Between Internal Structure (Cellulose Short Fibers/Collagen Composite) and Failure Strain

IWAMOTO Hiroshi; OKUBO Kazuya; TANAKA Tatsuya; FUJII Toru; ITO Noriichi

Transactions of the Japan Society of Mechanical Engineers Series B, The Japan Society of Mechanical Engineers, 73(734) 85 - 93, 25 Oct. 2007 - Effect of Pellet Geometry and Water Absorption on Strength of Long Jute Fiber Reinforced Polypropylene

SHIMA Kazuhiro; MIZOGUCHI Hironori; OKUBO Kazuya; FUJII Toru; TANAKA Tatsuya

Journal of the Society of Materials Science, Japan, The Society of Materials Science, Japan, 51(7) 826 - 831, 15 Jul. 2002

MISC

- The Optimization of Blister Disk Geometry for Mixing Performance in Co-Rotating Twin-Screw Extruder

Koki Matsumoto; Natsuki Kayamori; Tatsuya Tanaka; Yoshihiko Arao

PROCEEDINGS OF PPS-30: THE 30TH INTERNATIONAL CONFERENCE OF THE POLYMER PROCESSING SOCIETY, 1664, 2015 - Mechanical properties of injection-molded carbon fiber/polypropylene composites hybridized with nanofillers

Y. Arao; S. Yumitori; H. Suzuki; T. Tanaka; K. Tanaka; T. Katayama

COMPOSITES PART A-APPLIED SCIENCE AND MANUFACTURING, 55 19 - 26, Dec. 2013 - Hybrid effects on mechanical properties of injection molded nano-hybrid composites

Y. Arao; H. Suzuki; S. Yumitori; T. Tanaka; K. Tanaka; T. Katayama

ECCM 2012 - Composites at Venice, Proceedings of the 15th European Conference on Composite Materials, 01 Jan. 2012 - Development of the continuous process method for ECAP using a tri-axis rotary die and microstructural evolution of semi-solid aluminium alloy

K. Natori; F. Nomura; Y. Arao; T. Tanaka

WIT Transactions on the Built Environment, 124 107 - 117, 2012 - Proposal of sheet buckling design criteria for high strength steel under impact crushing

K. Watanabe; K. Natori; H. Enjoji; T. Tanaka; Y. Imaida

WIT Transactions on the Built Environment, 124 427 - 438, 2012 - 車体衝突時の鋼板エッジ破断簡易評価手法の開発 第2報

田中 達也; 渡辺憲一; 橘美枝; 小柳公人; 本村和嘉; 名取恵子

同志社大学理工学研究報告, 52(4) 253 - 260, 2011 - Study of the fracture limit evaluation method from the edge of steel sheet on the car crash (first report)

Watanabe Kenichi; Tachibana Mie; Koyanagi Kimihito; Motomura Kazuyoshi; Natori Keiko; Tanaka Tatsuya

The science and engineering review of Doshisha University, Doshisha University, 52(3) 189 - 196, 2011 - Development of forging process design to close internal voids

Hideki Kakimoto; Takefumi Arikawa; Yoichi Takahashi; Tatsuya Tanaka; Yutaka Imaida

JOURNAL OF MATERIALS PROCESSING TECHNOLOGY, 210(3) 415 - 422, Feb. 2010 - Study on a New Semi-Solid Injection Molding Method for Heat-Rresistant Magnesium Alloys : Trial Production and Process Verification of Machine

Tanaka Tatsuya; Imaida Yutaka; Shinozaki Kenji; Yoshida Makoto; Fujii Toshio

The science and engineering review of Doshisha University, Doshisha University, 51(2) 89 - 97, 2010 - Dual Phase 鋼板におけるBauschinger 効果のひずみ速度依存性

田中 達也; 渡辺憲一; 吉原伸太朗; 名取恵子; 今井田豊

日本塑性加工学会誌(塑性と加工), 51(594) 674 - 679, 2010 - Improvement of mechanical properties of semi-solid alloys by ECAP processing

Fumiya Nomura; Takuya Matsuba; Tatsuya Tanaka; Yutaka Imaida

MULTI-FUNCTIONAL MATERIALS AND STRUCTURES III, PTS 1 AND 2, 123-125 483 - 486, 2010 - Study on a New Semi-Solid Injection Molding Method for Heat-Resistant Magnesium Alloys ─Trial Production and Process Verification of Machine ─

TANAKA Tatsuya; 今井田豊; 篠崎賢ニ; 吉田誠; 藤井敏夫

The science and engineering review of Doshisha University, Doshisha University, 51(2) 89 - 97, 2010 - Study on the Bauschinger effect with increasing of tensile strength in dual phase steel sheets

K. Watanabe; K. Natori; T. Tanaka; Y. Imaida

HIGH PERFORMANCE STRUCTURES AND MATERIALS V, 112 119 - +, 2010 - Improvement of mechanical properties of long jute fiber reinforced polylactide prepared by injection molding process

T. Fujiura; T. Okamoto; T. Tanaka; Y. Imaida

DESIGN AND NATURE V: COMPARING DESIGN IN NATURE WITH SCIENCE AND ENGINEERING, 138 181 - +, 2010 - Process Design of Extend Forging Process Using Numerical Simulation Development of Process Design Method for the Finish Forging Process

Hideki Kakimoto; Yoichi Takashi; Hideki Takamori; Tatsuya Tanaka; Yutaka Imaida

MATERIALS TRANSACTIONS, 50(8) 1998 - 2004, Aug. 2009 - 数値シミュレーションを活用した鍛伸工程設計技術の開発-品質工学を用いた欠陥閉鎖工程設計手法の開発-

田中 達也; 柿本英樹; 有川剛史; 高橋洋一; 今井田豊

日本塑性加工学会誌(塑性と加工), 49(573) 1005 - 1010, 2009 - On how to reduce the fiber breakage during fabricating PP-based green composite pellets containing bamboo short fibers

久保田秀典; 藤井透; 大窪和也; 田中達也; 藤浦貴保; 長谷朝博

日本機械学会年次大会講演論文集, The Japan Society of Mechanical Engineers, 2008(Vol.1) 369 - 370, 02 Aug. 2008 - Extrusion

TANAKA Tatsuya

Journal of the Japan Society of Polymer Processing, プラスチック成形加工学会, 20(7) 375 - 385, 20 Jul. 2008 - A study on preparation and mechanical properties of long jute fiber reinforced polylactic acid by the injection molding process

T. Fujiura; K. Sakamoto; T. Tanaka; Y. Imaida

HIGH PERFORMANCE STRUCTURES AND MATERIALS IV, 97 231 - +, 2008 - Doshisha University, Faculty of Engineering, Department of Mechanical and System Engineering, Applied Materials Engineering Laboratory

TANAKA Tatsuya

Journal of the Japan Society of Polymer Processing, プラスチック成形加工学会, 19(10) 649 - 651, 20 Oct. 2007 - How to Improve Mechanical Properties of Polylactic Acid with Bamboo Fibers

田中 達也; R. Tokoro; D. Minh Vu; K. Okubo; T. Fujii; T. Fujiura

Journal of Material Science, 43 775 - 787, 2007 - ケーシングの破損に関する研究(破断ひずみと内部構造(セルロース短繊維/コラーゲン複合構造)の関係)

田中 達也; 岩元比呂志; 大窪和也; 藤井透; 伊藤典一

日本機械学会論文集, (734, A編) 1183 - 1191, 2007 - A study on mechanical performance of composites injection-molded from long jute fiber reinforced Polylactic Acid

田中 達也; 藤浦貴保; 今井田豊

Reinforced plastics, 強化プラスチック協会, 53(9) 430 - 436, 2007 - Study on a New Semi-Solid Injection Molding Method for Heat-Resistant Magnesium Alloys -Trisl Production and Process Verification-

Tanaka Tatsuya; Imaida Yutaka; Shinozaki Kenji; Yoshida Makoto; Fujii Toshio

The science and engineering review of Doshisha University, Doshisha University, 47(4) 209 - 215, 2007 - How to Improve Mechanical Properties of Polylactic Acid with Bamboo Fibers

TANAKA Tatsuya; R. Tokoro; D. Minh Vu; K. Okubo; T. Fujii; T. Fujiura

Journal of Material Science, 43 775 - 787, 2007 - Study on a New Semi-Solid Injection Molding Method for Heat-Resistant Magnesium Alloys─ Trial Production and Process Verification ─

Tanaka Tatsuya; Imaida Yutaka; Shinozaki Kenji; Yoshida Makoto; Fujii Toshio

The science and engineering review of Doshisha University, Doshisha University, 47(4) 209 - 215, 2007

Books etc

- 二軸押出機による樹脂混練 ―トラブル発生原因とその対策―

田中 達也

技術情報協会, 2011, Joint work, 45-67 - 竹の基礎科学と高度利用技術

田中 達也

シーエムシー出版, 2008, Joint work, 135-152 - 最新 ポリ乳酸の改質・高機能化と成形加工技術

田中 達也

技術情報協会, 2007, Joint work, 181-202

Presentations

- 酸性多糖類による高分子材料の難燃化に関する研究

浦上直人; 田中達也; 笹田昌弘

第15回自動車用途コンポジットシンポジウム, Nov. 2023, Nov. 2023, Nov. 2023 - セルロースファイバー強化ポリ塩化ビニル樹脂の特性向上に関する研究

馬場晴也; 田中達也; 笹田昌弘; 宮本佳奈

第15回自動車用途コンポジットシンポジウム, Nov. 2023, Nov. 2023, Nov. 2023 - 伸長流動を応用したん軸押出機によるポリマーアロイの分散混合に関する研究

田中美伶; 田中達也; 笹田昌弘; 松本昌和

プラスチック成形加工学会 第31回秋季大会, Nov. 2023, Nov. 2023, Nov. 2023 - 二軸押出機を用いた伸長流動によるポリエチレンテレフタレート/ポリプロピレンの分散混合に関する研究

日隈大介; 田中達也; 笹田昌弘; 北村広之

プラスチック成形加工学会 第31回秋季大会, Nov. 2023, Nov. 2023, Nov. 2023 - 射出成形における溶融樹脂の機械学習予測

紀藤駿介; 田中達也; 笹田昌弘; 下楠薗壮; 井上玲

第15回自動車用途コンポジットシンポジウム, Nov. 2023, Nov. 2023, Nov. 2023 - 3Dプリンタ用連続炭素繊維強化フィラメントの製造方法および特性向上に関する研究

細川皓矢; 田中達也; 笹田昌弘

プラスチック成形加工学会 第31回秋季大会, Nov. 2023, Nov. 2023, Nov. 2023 - 二軸押出機を用いた混練プロセスにおける炭素繊維の折損に関する研究

堀口栞; 田中達也; 笹田昌弘; 石川健

プラスチック成形加工学会 第31回秋季大会, Nov. 2023, Nov. 2023, Nov. 2023 - Effect of Diameter of Fulcrum Roller on Shape of Rebar in Bending

S. Higaki; T. Go; K. Mizuno; M. Sasada; T. Tanaka

The 14th International Conference on the Technology of Plasticity, Sep. 2023, 24 Sep. 2023, 29 Sep. 2023 - ポリプロピレンの伸長レオロジーがカーボンナノチューブの分散に与える影響

藤澤 勇哉; 竹村 兼一; 松本 紘宜; 田中 達也

プラスチック成形加工学会 第34回年次大会, Jun. 2023, Jun. 2023, Jun. 2023 - 射出成形における可塑化樹脂の均一化

紀藤駿介; 田中達也; 笹田昌弘; 下楠薗壮; 井上玲

プラスチック成形加工学会34回年次大会, Jun. 2023, Jun. 2023, Jun. 2023 - Study on the Behavior of Carbon Fibers in the Kneading Process Using Twin-Screw Extruders

Horiguchi Shiori; Tanaka Tatsuya; Sasada Masahiro; Ishikawa Takeshi

38th International Conference of the Polymer Processing Society, May 2023, 22 May 2023, 26 May 2023 - Extensional Flow Effect on Dispersion in Twin-Screw Extruder:DURABIO/PMMA Polymer Alloys

Birei Tanaka; Tatsuya Tanaka; Masahiro Sasada; Akikazu Matsumoto

38th International Conference of the Polymer Processing Society, May 2023, 22 May 2023, 26 May 2023 - 連続混練押出機を用いたセルロースファイバー添加ゴム複合材料の分散混練に関する研究

江南勇汰; 田中達也; 笹田昌弘; 遠藤貴士; 幕田悟史

日本機械学会第28回機械材料・材料加工技術講演会, Nov. 2020 - 射出成形におけるセンシング技術を用いた樹脂均一溶融の評価

山本良平; 田中達也; 笹田昌弘; 下楠薗壮

プラスチック成形加工学会第31回年次大会, Jun. 2020 - 誘導加熱による熱可塑性樹脂の高速均一溶融に関する研究

松村賢侑; 生嶋壮基; 田中達也; 笹田昌弘; 下楠薗壮

プラスチック成形加工学会第31回年次大会, Jun. 2020 - ナノ繊維・粒子の最適制御技術 を基盤とする新規複合材料機能 の開発

田中達也; 大窪和也; 田中和人; 加藤将樹

第27回成形加工シンポジア'19, 12 Nov. 2019, Keynote oral presentation - Effect of Using the V&D Screw on the Mechanical Properties of Carbon/Aramid Long Fiber Reinforced Thermoplastic Resin

K.Kazuya; K.Fujisaki; T.Tanaka; M.Sasada; S.Shimokusuzono

22nd International Conference on Advances In Materials & Processing Technologies, 21 Oct. 2019, 23 Oct. 2019 - MOLTEM STATE OF THERMOPLASTIC RESIN AN INJECTION MOULDING BARREL

So.Shimokusuzono; T.Tanaka; M.Sasada; Y.Hirao; K.Hanafusa; A.Inoue

19th International Conference on Computation Method and Experimental Measurements, 03 Jun. 2019, 05 Jun. 2019 - 繊維強化熱可塑性樹脂複合材料の直接整形技術の研究

西野裕哉; 田中達也; 笹田昌弘; 樋口亮平; 谷垣健志

プラスチック成型加工学会 第30回年次大会, Jun. 2019 - 二軸押出機におけるセグメント構成が炭素繊維分散性に及ぼす影響

塩崎玲; 田中達也; 笹田昌弘; 石川健; 奥中理

プラスチック成型加工学会 第30回年次大会, Jun. 2019 - Improvement of interfacial adhesion using CNTs-containing films in hybrid injection molding (HIM)

Y.Hirao; T.Tanaka; M.Sasada; T.Ishikawa

International Conference on Materials Research & Nanotechnology, Jun. 2019 - Effect of Injection molding process using induction heating on mechanical properties of long glass fiber reinforced

K.Fujisaki; T.Tanaka; S.Shimokusuzono; T.Matsumura; M.Nakajima; T.Maenaka; A.Inoue; M.Okazaki

Polymer Processing Society Americas Regional Conference 2018, Nov. 2018 - A Study on elucidation of the fiber dispersion mechanism for production of high-dispersion length fiber pellets

H.Goto; T.Tanaka; T.Fujiura

Polymer Processing Society Americas Regional Conference 2018, Nov. 2018 - Influence of contents rate and dispersion of carbon nanotubes on interfacial between continuous fiber reinforced thermoplastics and injection resin

H.Nishino; K.Matsumoto; J.Shiode; T.Tanaka

13th International Conference on Textile Composites, 17 Sep. 2018, 19 Sep. 2018 - Comparison of strength of 3D printing objects using short fiber and continuous long fiber

T.Isobe; T.Tanaka; T.Nomura; R.Yuasa

13th International Conference on Textile Composites, 17 Sep. 2018, 19 Sep. 2018 - Establishment of New Molding System for Long Fiber Reinforced Thermosetting Resin

K.Fujisaki; H.Goto; T.Tanaka; M.Nakajima; T.Maenaka; A.Inoue; M.Okazaki

34th International Conference of the Polymer Processing Society, May 2018 - Flow behavior of thermoplastic resin in the barrel of injection molding

Y.Hirao; S.Shimokusuzono; T.Tanaka

34th International Conference of the Polymer Processing Society, May 2018 - Compression properties of the inorganic filler-thermoplastic composites

K.Masuyama; T.Tanaka; M.Betsudan

2017 3rd International Conference on Architecture, Materials and Construction (ICAMC2017), 11 Dec. 2017, 13 Dec. 2017 - Effect of carbon nanotube inserted to the interface of hybrid CFRTP specimens on adhesive strength

K.Matsumoto; J.Shiode; T.Tanaka

20th International Conference on Composite Structure, 04 Sep. 2017, 07 Sep. 2017 - Improvement in mechanical properties of semi-solid AA 7075 aluminum alloys by Equal-Channel Angular Pressing

G.Horikiri; T.Kitazumi; K.Natori; T.Tanaka

International Conference on the Technology of Plasticity, Sep. 2017 - An investigation on dispersion state of graphene in polypropylene / graphite nanocomposite with extensional flow mixing

K.Matsumoto; Y.Nakade; K.Sugimoto; T.Tanaka

The 32nd International Conference of the Polymer Processing Society, Jul. 2017 - Influence of Agitation Equipment on Reinforcing Effect and Dispersion State of Cellulose Nano-Fibers in Natural Rubber

S.Omori; T.Morita; K.Matsumoto; A.Nagatani; T.Tanaka

16th International Conference on Fracture and Damage Mechanics, Jul. 2017 - New Screw Design Induced Extensional Flow for Enhancement of CNT Dispersion in PP Matrix through Twin-screw Extruder

K.Matsumoto; T.Tanaka

PPS Europe Africa Conference 2017, 26 Jun. 2017, 29 Jun. 2017 - PLA/CNT複合材料を用いた3Dプリンタ成形品の機械的特性に関する研究

磯部貴之; 荒木邦紘; 濱邊剛至; 田中達也; 埜村卓志; 湯浅亮平

プラスチック成型加工学会 第28回年次大会, 14 Jun. 2017, 15 Jun. 2017 - 無機フィラー含有熱可塑性樹脂複合材料の圧縮強度の向上に関する研究

増山健太; 田中達也; 別段碧

プラスチック成型加工学会 第28回年次大会, 14 Jun. 2017, 15 Jun. 2017 - Effect of screw design on fiber breakage and dispersion of FRTP in injection molding

S.Shimokusuzono; T.Tanaka; A.Inoue

PPS Europe Africa Conference 2017, Jun. 2017 - Study on friction and abrasion properties of wood plastic composites

K.Araki; G.Hamabe; Y.Sano; T.Kume; T.Tanaka

The 2016 International Conference on High Performance and Optimum Design of Structures and Materials, Sep. 2016 - Improvement in toughness of semi-solid light metal by ECAP process

T.Kitazumi; K.Natori; T.Tanaka

The 2016 International Conference on High Performance and Optimum Design of Structures and Materials, Sep. 2016 - プラスチック成形機における新規スクリュ形状を考案するための開発手法

岩﨑顕光; 塩出純也; 田中達也; 井上玲; 下楠薗壮

プラスチック成型加工学会 第27回年次大会, Jun. 2016 - 超小型射出成形機におけるフラットスクリュの最適化

坪田廉孝; 田中達也

プラスチック成型加工学会 第27回年次大会, Jun. 2016 - 真空断熱容器の構造設計に関する研究

田中達也; 堀内拓也; 林弘貴

日本設計工学会2016年度春季大会研究発表講演会, May 2016 - 半凝固軽金属微細化材料による超薄肉箱成形の研究”,

田中 達也

第43回塑性加工春季講演会講演, 2012 - 発泡樹脂におけるフィラー分散が気泡形成に及ぼす影響

田中 達也

成形加工’12,第23回プラスチック成形加工学会講演, 2012 - 二軸押出機によるカーボンナノチューブの分散混練

田中 達也

成形加工’12,第23回プラスチック成形加工学会講演, 2012 - 天然繊維強化複合材料の強度向上に関する研究

田中 達也

成形加工’12,第23回プラスチック成形加工学会講演, 2012 - Forming of housing by impact extrusion press using ultrafine-grained semi-solid light metal

TANAKA Tatsuya

The 7th Australasian Congress on Applied Mechanics, 2012 - Study on Impact Crushing Properties of High Strength Steel Sheets

TANAKA Tatsuya

Collaborative Research Centre Transregio 30,1st International Conference on Thermo-Mechanically Graded Materials, 2012 - Study on the structual design of a bottle with vacuum insulation structure

TANAKA Tatsuya

The Eleventh International Conference on Computational Structures Technology, 2012 - Effects of lignin content on the mechanical properties of PP/wood flour composites

TANAKA Tatsuya

2012 International Conference on Electronic and Materials, 2012 - Effect of flow in tube on morphology and mechanical properties of PP/clay nanocomposite

TANAKA Tatsuya

2012 International Conference on Electronic and Materials, 2012 - Mechanical and Tribological Properties of Nanocomposites Made of Eco-Friendly Resin

TANAKA Tatsuya

2012 International Conference on Electronic and Materials, 2012 - Hybrid effects on mechanical properties on injection molded nano-hybrid composites

TANAKA Tatsuya

ECCM-15, 2012 - Visualization of starved flow in an intermeshing region of a twin-screw extruder

TANAKA Tatsuya

Polymer Processing Society Americas Conference 2012, 2012 - Study on the effect of screw geometries on fiber length and dispersion of GFRTP in injection molding

TANAKA Tatsuya

Polymer Processing Society Americas Conference 2012, 2012 - 各種繊維強化複合材料のスクリュ形状と機械的特性に関する研究

田中 達也

第3回自動車用途コンポジットシンポジウム, 2011 - リグニンを添加した熱可塑性樹脂の特性に関する研究

田中 達也

第3回自動車用途コンポジットシンポジウム, 2011 - BFRPの射出成形における残存繊維長及び繊維分散性に関する研究

田中 達也

56th FRP CON-EX2011, 2011 - ジュート強化ポリ乳酸射出成形材の機械的特性に及ぼす繊維分散の影響

田中 達也

56th FRP CON-EX2011, 2011 - リグニンを添加した熱可塑性樹脂の特性に関する研究

田中 達也

56th FRP CON-EX2011, 2011 - 高張力鋼板の座屈現象に関する研究

田中 達也

第42回塑性加工春季講演会講演, 2011 - ジュート強化ポリ乳酸射出成形材の機械的特性に及ぼす繊維分散の影響

田中 達也

成形加工’11,第22回プラスチック成形加工学会講演, 2011 - 二軸押出機内の流動挙動の可視化

田中 達也

成形加工’11,第22回プラスチック成形加工学会講演, 2011 - 射出成形におけるスクリュ形状によるGFRPの繊維長及び繊維分散性

田中 達也

成形加工’11,第22回プラスチック成形加工学会講演, 2011 - 発泡樹脂におけるフィラー分散の影響に関する研究

田中 達也

成形加工’11,第22回プラスチック成形加工学会講演, 2011 - ポリマー/クレーナノコンポジット製造プロセスの研究

田中 達也

成形加工’11,第22回プラスチック成形加工学会講演, 2011 - リグニンを添加した熱可塑性樹脂の特性に関する研究

田中 達也

成形加工’11,第22回プラスチック成形加工学会講演, 2011 - 射出成形におけるスクリュ形状の違いによるGFRPPの繊維長及び繊維分散性

田中 達也

日本機械学会関西支部,第86期定時総会講演会, 2011 - Mechanical Behavior of Lignin/Polymer Composites

TANAKA Tatsuya

19th Annual BEPS Meeting, 2011 - Shape Prediction of Incremental Forming with Hammer

TANAKA Tatsuya

10th International Conference on Technology of Plasticity, 2011 - Strain Rate Dependence of Sheet Buckling in High Strength Steel Sheets

TANAKA Tatsuya

10th International Conference on Technology of Plasticity, 2011 - An Optimum Design Index of the Bottle with the Vacuum Insulation Structure

TANAKA Tatsuya

The 8th International Conference and Workshop on Numerical Simulation of 3D Sheet Metal Forming Processes, 2011 - Strength improvement of jute fiber-reinforced composite material

TANAKA Tatsuya

6th International Conference on Advanced Materials Development and Performance, 2011 - Study on Injection Molding of Glass Fiber Reinforced Polypropylene with Fiber Length and Dispersion

TANAKA Tatsuya

Plastic Injection Molding Asia 2011, 2011 - Study on Impact Crushing Properties of High Strength Steel Sheets

TANAKA Tatsuya

14th International Conference on Sheet Metal, 2011 - ジュート強化ポリ乳酸射出成形材の機械的特性に及ぼす繊維分散の影響

田中 達也

第2回自動車用途コンポジットシンポジウム, 2010 - 射出成形機におけるスクリュ形状の違いによるGFRPPの繊維長と繊維分散性

田中 達也

第2回自動車用途コンポジットシンポジウム, 2010 - ジュート強化ポリ乳酸射出成形材の機械的特性に及ぼす繊維分散の影響

田中 達也

第18回成形加工シンポジア’10, 2010 - ガラス繊維強化ポリプロピレンの射出成形における繊維長および分散性に関する研究

田中 達也

第18回成形加工シンポジア’10, 2010 - シミュレーションを用いた二軸押出機による分散混練の研究

田中 達也

第18回成形加工シンポジア’10, 2010 - ポリマー/クレーナノコンポジット製造プロセスの研究

田中 達也

第18回成形加工シンポジア’10, 2010 - シミュレーションを用いた二軸押出機による分散混練の研究

田中 達也

成形加工’10,第21回プラスチック成形加工学会講演, 2010 - ポリマー/クレーナノコンポジット製造プロセスの研究

田中 達也

成形加工’10,第21回プラスチック成形加工学会講演, 2010 - 衝撃押出し成形法の最適化に関する研究

田中 達也

第61回塑性加工連合講演会講演, 2010 - ハンマーによる薄板インクリメンタル成形の自動化に関する研究

田中 達也

第61回塑性加工連合講演会講演, 2010 - 半凝固軽合金材料におけるECAP加工による高靭性化の研究

田中 達也

第61回塑性加工連合講演会講演, 2010 - Study on the Optimization of the Screw Segment Composition of the Nano-Clay Reinforced Elastomer Composite by Twin Screw Extruder”,The Polymer Processing Society

TANAKA Tatsuya

Proc. of the international conference on the PPS 2010 Meeting, 2010 - A Study on Fabricating Metal Composite Foam Panels with the Use of Clay Fillers for the Control of Cell Structure

TANAKA Tatsuya

The Polymer Processing Society,Proc. of the international conference on the PPS 2010 Meeting, 2010 - 医療福祉機器の最適軽量化に関する研究

田中 達也

日本設計工学会,関西支部研究発表講演会, 2009 - フィラー分散樹脂を芯材として発泡樹脂金属複合板のプロセス研究

田中 達也

成形加工’09,第20回プラスチック成形加工学会講演, 2009 - BFRPPの射出成形における繊維長と分散性に関する研究

田中 達也

成形加工’09,'第20回プラスチック成形加工学会講演, 2009 - ナノ粒子強化熱可塑性エラストマー複合材料に関する研究

田中 達也

成形加工’09,第20回プラスチック成形加工学会講演, 2009 - 半凝固材料におけるECAP微細加工での機械的特性の研究

田中 達也

第40回塑性加工春季講演会講演, 2009 - 衝撃押出し成形の最適化に関する研究

田中 達也

第40回度塑性加工春季講演会講演, 2009 - 液中放電成形法によるマイクロ張出し成形に関する研究

田中 達也

第40回度塑性加工春季講演会講演, 2009 - 天然繊維強化ポリ乳酸の加水分解が機械的性質に及ぼす影響

田中 達也

JCOM-38講演, 2009 - カーボン長繊維/短繊維強化熱可塑性樹脂の成形性及び機械的特性に関する研究

田中 達也

JCOM-38講演, 2009 - Improvement of Mechanical Properties of Long Jute Fiber Reinforced Polylactic Acid Prepared by Injection Molding Process Process

TANAKA Tatsuya

Third China-Japan Joint Seminar on Green,Composites, 2009 - 圧縮予ひずみを受けるDP型高張力鋼板のひずみ速度依存性に関する研究

田中 達也

第59回塑性加工連合講演会講演, 2008 - 噛み合い方同方向二軸押出機のニーディングディスクにおける応力解析に関する研究

田中 達也

成形加工’08,第19回プラスチック成形加工学会講演, 2008 - 竹繊維強化ポリプロピレンの混練および成形に関する研究

田中 達也

成形加工’08,第19回プラスチック成形加工学会講演, 2008 - ナノ粒子強化熱可塑性エラストマー複合材料に関する研究

田中 達也

成形加工’08,第19回プラスチック成形加工学会講演, 2008 - 水中放電成形法によるマイクロ張出し成形に関する研究

田中 達也

第39回塑性加工春季講演会講演, 2008 - 衝撃押出しの最適化に関する研究

田中 達也

第39回塑性加工春季講演会講演, 2008 - 高張力鋼板におけるバウシンガー効果のひずみ速度依存性

田中 達也

第39回塑性加工春季講演会講演, 2008 - 半凝固材料におけるECAP微細加工での機械的特性の研究

田中 達也

第39回塑性加工春季講演会講演, 2008 - Influence of moisture in the mechanical properties of long jute fiber reinforced polylactic acid

TANAKA Tatsuya

第45回理工学研究所研究発表会, 2007 - 高圧ホモジナイザーによる高濃度ナノコンポジットの製造に関する研究

田中 達也

第15回成形加工シンポジア’07, 2007 - 和竹繊維強化ポリプロピレンペレット製造技術の開発

田中 達也

第15回成形加工シンポジア’07, 2007 - ジュート長繊維強化ポリ乳酸の機械的特性に及ぼす水分の影響

田中 達也

第15回成形加工シンポジア’07, 2007 - Influence of moisture in the mechanical properties of long jute fiber reinforced polylactic acid

TANAKA Tatsuya

Second China-Japan Joint Seminar on Green Composites, 2007

Industrial Property Rights

- Patent right

成形システム

田中達也, 藤崎謙, 井上玲, 岡崎雅則, 中島真敏

特願2017-253864 - Patent right

成形品およびその製造方法

冨岡正雄, 石川健, 田中達也, 塩出純也, 松本紘宜

特願2017-034020

Research Projects

- 強ひずみ加工法により作製した超微細結晶組織材料の逐次加工性向上

田中 達也; 宮本 博之

日本学術振興会, 科学研究費助成事業, 2022/04 -2025/03, 基盤研究(C), 同志社大学 - Enhanced compressibility of ultrafine-grained semi-solid two-phase aluminum alloys

Tanaka Tatsuya

Ultrafine grained materials or nanocrystalline materials should have high formability under high compressive stress state because they have low strain hardening capability due to their unique deformation mechanism involving grain boundary sliding. Target materials was changed from semi-solid Al-Si alloys to copper of commercial purity because it was difficult to fragment the second Si phase by ECAP for Al-Si alloys, which is essential to obtain high formability. However, it was found that even pure copper have high potential to exhibit high compressive formability., Japan Society for the Promotion of Science, Grants-in-Aid for Scientific Research, 2019/04 -2022/03, Grant-in-Aid for Scientific Research (C), Doshisha University - Development of continuous high-pressure torsion for the mass production of high-strength aluminum alloy

Tanaka Tatsuya

Torsion extrusion (TE) is one of severe plastic deformation (SPD), where a long bar billet is subjected to shear strain with extrusion. This is an improved processing of high-pressure torsion (HPT) whose disadvantage is batch processing applicable for only short or small billet. However, in conventional TE, deformation processing is composed of two parts, which are extremely localized straining and rigid body rotation. Thus, the deformation is not efficient in view of grain size reduction and strengthening. In this project, we developed new type of TE where shear straining can be applied in more effective manner by modifying die geometry so that shear strain become more uniform throughout deformation process. We demonstrated the grain size is become smaller than that by the conventional process., Japan Society for the Promotion of Science, Grants-in-Aid for Scientific Research, 2014/04 -2016/03, Grant-in-Aid for Challenging Exploratory Research, Doshisha University - Research on the forming process square shape of the super-thin wall housing case by newly made light-alloy matal with the high mechanical property

TANAKA Tatsuya

Semi-solid casting of AC4CH aluminum alloy (hereinafter, SS) was used for this research. Furthermore, ultrafine-grained metal (hereinafter, SS-ECAP) was fabricated by Equal-Channel Angular Pressing using SS material. Formability of these test materials was evaluated by an impact molding method to form thin-walled housing. This method is how to give impact load to the light weight metal of bulk at high speed, and extrude to backward from narrow clearance by high pressure. As a result, AC4CH aluminum alloy modified by semi-solid casting and ECAP processing achieve the improvement in not only the mechanical property but also the workability in impact process. Although it is known that the impact extrusion process can be performed stably to produce the thickness larger than 0.7 mm, a housing having super-thin walled square cross-section with 0.4 mm in thickness can be formed from SS-ECAP material., Japan Society for the Promotion of Science, Grants-in-Aid for Scientific Research, 2011 -2013, Grant-in-Aid for Scientific Research (C), Doshisha University - Research which creates a heat-resistant Magnesium alloy into material with high toughness using a continuation ECAP micro-machining method with six axes.

TANAKA Tatsuya

In order to check the extrusion form at the time of continuation processing and improve the mechanical properties, the AC4CH aluminum casting alloy was extruded by the 6 axes ECAP method. When back pressure was applied, generating of the void due to a rapid pressure drop was suppressed. As a result, the improvement in a tensile strength was remarkable at semi-solid material. Furthermore, a continuous feeding is possible for the shape by which was extruded enough to the next pass. As a result, the distortion was maintained by the semi-solid casting and creation of the material whose strength improved by the addition to ECAP method was attained., Japan Society for the Promotion of Science, Grants-in-Aid for Scientific Research, 2008 -2010, Grant-in-Aid for Scientific Research (C), Doshisha University - エアープラズマ処理による天然長繊維強化ポリ乳酸樹脂複合材料の高性能化

田中 達也

平成19年度の成果として,天然繊維(ジュート繊維)中の含水分がポリ乳酸樹脂の加水分解にどのように影響しているかを調べた.その結果,ポリ乳酸樹脂との複合化前のジュート繊維の乾燥状態および造粒(ペレット)後の乾燥条件によって含水分量は変化し,ペレット含水分量と射出成形後のポリ乳酸の分子量には負の相関があり,射出成形での可塑化中にも加水分解によるポリ乳酸の劣化(生分解)が進んでいることが明らかになった.また,ポリ乳酸の分子量低下は機械的特性も低下させ,ジュート繊維で強化させているにも関わらずペレット時の含水分量が1wt%を超えると分子量が半減し,元のポリ乳酸ペレット(分子量が低下していない状態)で射出成形した機械的特性の結果よりも低くなった.さらに,成形品中でも天然繊維内部に抜けきらない水分が残存すると,成形品の乾燥によっても変形と同時にポリ乳酸の分子量は低下することが分かり,ペレットにするまでの段階で如何に繊維内部の水分を除去できるかが,機械的特性向上の課題であり,繊維内部の水分が抜け易い構造の長繊維ペレットが有効であることを示した.一方,上記結果よりペレット製造時のエアープラズマ処理およびエアーブロー処理によるオンラインでジュート繊維内部の含水分率を1wt似下に除去することは極めて困難であった.オフラインでの熱風乾燥および誘導加熱によってジュート繊維は短時間で繊維内部まで水分除去に効果があることが分かったが,紡績糸の供給形態であるボビン状(紙管に巻かれた状態)では,加熱時間の増加と共に熱が中心部に蓄積され繊維が熱劣化し,ジュート繊維の加熱方法に課題を残した.エアープラズマ処理による界面改質の効果の有無に関しては,含水分の影響が極めて大きいためその傾向は見出せなかった.しかし,ジュート繊維との複合化によりポリ乳酸の耐熱性に向上は見られた., 日本学術振興会, 科学研究費助成事業, 2006 -2007, 若手研究(スタートアップ), 同志社大学 - Development of green composites using thermoplastics and bamboo fiber

FUJII Toru; OKUBO Kazuya; TANAKA Tatusya

Bamboo fibers were extracted from raw bamboo such as Moso (Chinese) and Madake (a typical Japanese bamboo) by following three methods. (1) Mechanical processing by using the conventional fiber loosening machine. It has a rotating nail drum where thin bamboo strips are used. Younger bamboo than one year old is suitable for this method. (2) Alkali (NaOH) treatment: First, bamboo strips are immersed in a hot alkali bath for a couple hours, then, they are machined(3) Steam explosion method: Raw bamboo is set in a steam chamber which will be filled with super heated steam at high pressure. Then, the steam is abruptly released. Micro-cell explosion occurs in cells. Then, fibers are extracted by using the loosing machine from steam exploded bamboo. Relatively long fibers are obtained by the alkali treatment and the steam explosion method while short fibers are extracted when bamboo is mechanically processed. However, long fibers can be obtained enough to be used for fabricating non-woven fabrics by mixing thermoplastic (TP) fibers as long as the bamboo is very young. Non-woven fabrics using relatively short bamboo fibers as well as TP fibers such as PP and PE were successfully developed. It can be used as a green composite material to form inner components of automobiles such as ceiling and rear trays. PIA (Poly Lactic Acid) fibers made from corns can also be used instead of PP fibers. Fibers shorter than 50 mm are mixed with TP using a twin screw extruder to fabricate green composites pellets. In order to increase the tensile/bending strengths of the injection molded parts, the bamboo fiber diameter is a key as well as the aspect ratio. Thinner than 0.1 mm is desirable for the nominal diameter of bamboo fibers as well as a high aspect ratio greater than 20. Through the twin extruder path, the aspect ratio of bamboo fibers in a composite decreases. The maximum tensile strength of a bamboo fiber (50%wt content) /PP composite is about 50 Mpa. The maleic acid modification is obliged to increase the mechanical properties of bamboo fiber green composites. The mechanical properties of random bamboo fiber mats/Polyester composites (BFRP) were measured. The BFRP was fabricated by RTM (Resin Transfer Molding) while long bamboo fibers were extracted from MOSO bamboo by the alkali treatment. The bamboo mats were fabricated by using a carding machine in conjunction with a needle punching machine. The mats was very thick and the resultant BFRP had a low strength not enough to use for fabricating small boats (5 m long). Then, in order to increase the bamboo fiber fraction, bamboo mats were compressed in advance and used. The observed strength of the improved BFRP is strong enough to use for the boats. However, the study on water absorption tells us to pay a lot of attention on water. An appropriate treatment to prevent the water absorption during service is strongly suggested. The present study shows that not only the mechanical properties of PIA but also the heat resistance at elevated temperature are well improved due to inclusion of micro-fibrillated bamboo fibers. Short bamboo fibers can enhance the tensile strength and heat resistance, but the impact strength becomes low due to bamboo fibers. On the other hand, if the bamboo fibers are slightly fibrillated, the impact strength is well improved. Finally, the mechanical and thermal properties of the composite materials based on PLA are sometimes higher than those of 20 wt% glass fiber/ABS composite. The fibrillated bamboo fibers are also applied to fabricate the proving disks for semi-conductors., Japan Society for the Promotion of Science, Grants-in-Aid for Scientific Research, 2005 -2007, Grant-in-Aid for Scientific Research (B), Doshisha University

Research Seeds

- Development of high-strengh and high-toughness magnesium by the control of solid-phase rate of semi-solid metal and by together use of ECAP methodResearch Fields: Machinery and Measuring EquipmentAffiliation/Name: Tatsuya Tanaka

Patent Information: 特許第5202038号

Patent Information: 特許第5202038号 - Development of high-performance materials for 3D printerResearch Fields: Machinery and Measuring EquipmentAffiliation/Name: Tatsuya Tanaka

Patent Information: 特願 2014-143891

Patent Information: 特願 2014-143891